Thai Natural Fibers Co., Ltd. (TNF)

We are the manufacturer of coconut coir fiber, coco peat, coco chips and made-to-order growing medium or substrate. We have been in the coconut coir fiber business for over twenty years. With our experience and expertise in this business, you can be sure to receive products that meet your need and expectation. Our customers are both domestics and export to China and Malaysia.

Production Process

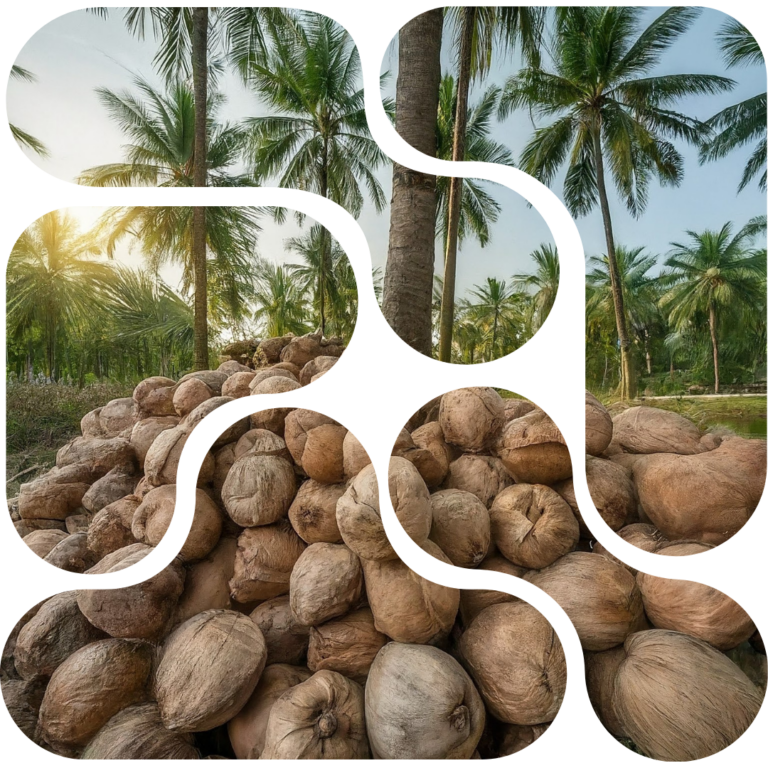

The manufacturing process starts from gathering and collecting coconut husks from local households, nearby province such as Ranong and Koh Samui and coconut plantations. Coconut husks are then fed to the extraction machine. The machine extracts the fiber from coconut husk and produce fibrous material or so-called coconut coir fiber. This process produces both coir fiber and coco peat.

Coir fiber is being moisture controlled to meet customer moisture specification which is typically less than 20% by using sunlight or steam boiler heat to dry for approximately 8-10 hours. After that it is semi-pressed into bale and transport to port.

At our factory, we can produce a wide range of coco peat products depending on customer’s requirement. Whether it’s finely sieved coco peat or partially sieved coco peat or washed coco peat (pH and EC controlled).

We have plenty of coconut husk chopping machines for producing medium or small size coconut husk chopped chips (coco chips).

In the manufacture of growing substrate, the customer can specify the mixture proportion of coco peat, coco chips and fiber. All ingredients are thoroughly mixed to suit the plants that need to be cultivated.

Our mission

To manufacture high and premium quality products whilst being environmentally and community friendly.

Our Products Products

Coconut coir or fiber is a natural fibrous material extracted from the coconut husks. The coconut coir fiber is long and brown in colour. It is known for its strength and resistance to damage. It is typically used in bed mattress, upholstery, doormat, and rope

Short or baby fiber is similar to coconut coir fiber but shorter in length. Its length varies from 1-10 cm. It is produced by screening of coco peat. It is used in soil mix to improve drainage and aeration of the soil, allowing the roots to grow well.

Sieved coco peat is regular coco peat that has been sifted through various sizes mesh to reduce the number of fibers in order to suit a specific type of cultivation. Some plants require coco peat that has fewer fibers than regular coco peat to enhance the water-holding efficiency and hence robust root growth.

Low EC, sieved coco peat is produced by screening or sifting of coco peat to obtain the finest coco peat. After that, it undergoes a water rinsing process to control the electrical conductivity (EC). Typically, a low EC value is a value equal or below 0.5 mS/cm. This type of coco peat is fine-grained and fiber free. It retains moisture well and has optimal EC and pH value. It is suitable for seedling and cultivation.

Coconut husk chopped chips or coco chips are produced by feeding coconut husks through a chopping machine. The machine can produce in either small or medium size chips. It is commonly use in soil mix or place at the bottom of the plant pots to help keep the soil loose and drain well

Growing substrate is a made-to-order combination of coco peat, coconut fiber and coconut chopped chips to suit a customer's specific cultivation.

Contact us

Telephone :

077-510962

Fax :

077-512456

Email :

info@thainaturalfibers.com

Address :

99 Mu 14, Nasak, Sawee, Chumphon 86130